You are here

Le Rhône 9J Engine History

The Le Rhône 9J is a nine-cylinder rotary aircraft engine produced in France by Gnome et Rhône. Also known as the Le Rhône 110 hp in a reference to its nominal power rating, the engine was fitted to a number of military aircraft types of the First World War. Le Rhône 9J engines were produced under license in Great Britain by W.H. Allen Son & Company of Bedford, and in Germany by Motorenfabrik Oberursel.

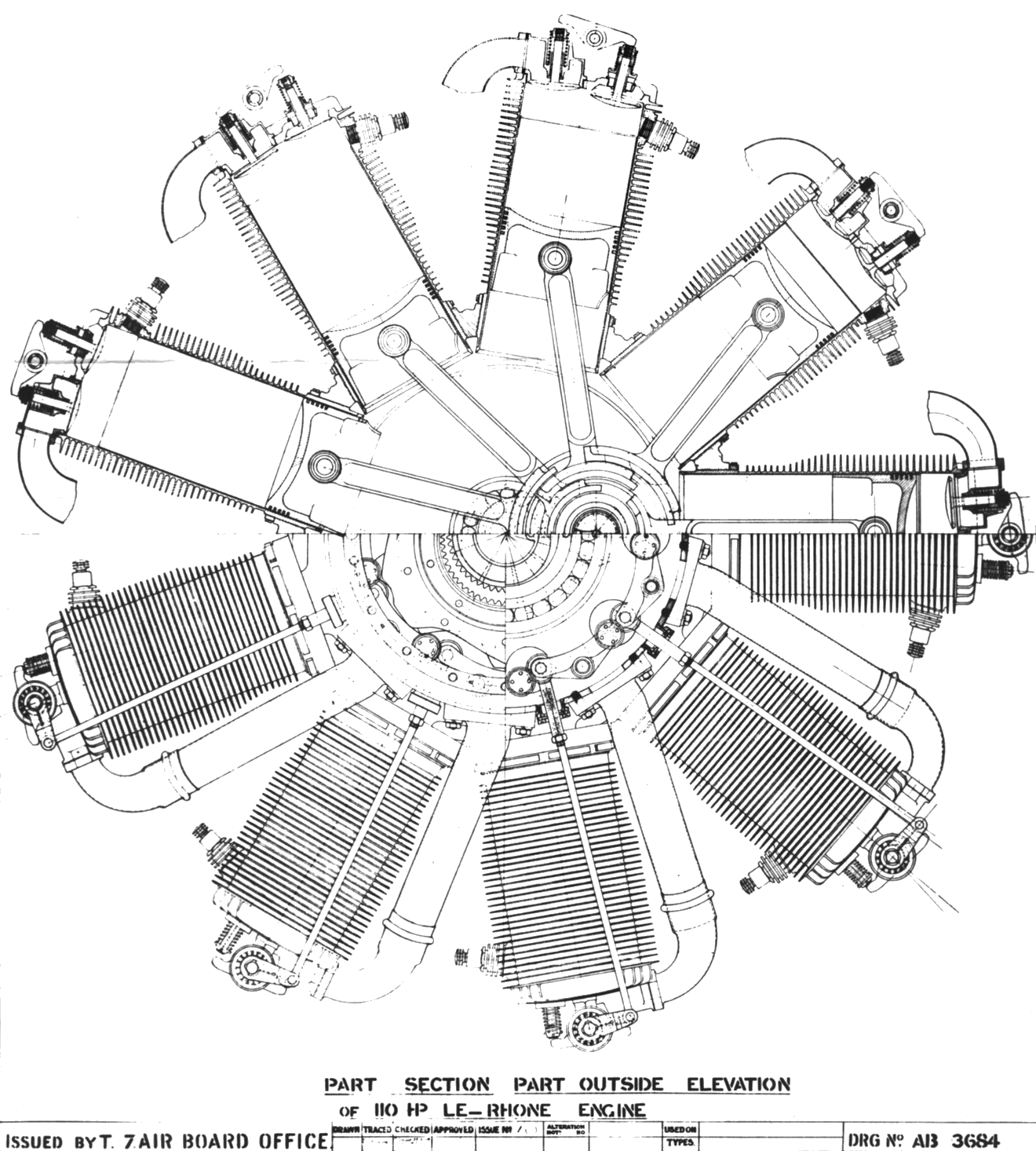

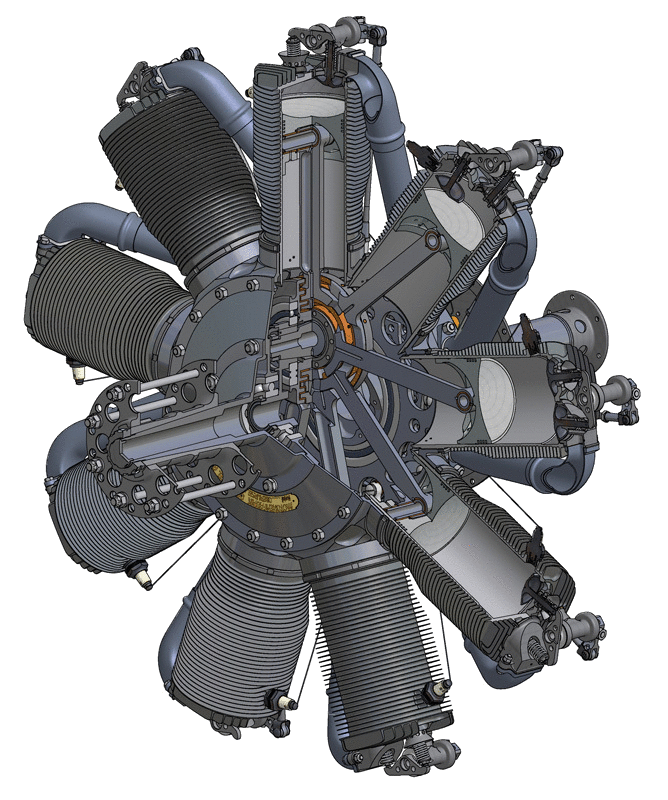

In common with other Le Rhône series engines, the 9J featured highly visible copper induction pipes and used a single push-pull rod to operate its two overhead valves. The main visual difference between the 9J and the earlier, less powerful Le Rhône 9C engine is that the copper intake manifold tubing (with round section lower ends) on the 110 hp 9J is attached to the crankcase behind the cylinders, whereas on the 9C (80 hp) the intake manifolds (with rectangular lower ends) are fully visible from the front.

The engine was manufactured under license in Germany by Motorenfabrik Oberursel and sold as the Oberursel UR.II.

The engine was manufactured under license in Germany by Motorenfabrik Oberursel and sold as the Oberursel UR.II.

The copper induction tubes had their crankcase ends located in different places on the 80 and 110 horsepower (60 and 82 kW) versions – the 80 hp versions had them entering the crankcase in a location forward of the vertical centerline of each cylinder, while the 110 hp version had them located behind the cylinder's centerline. This resulted in the 80 hp version's intake plumbing being "fully visible" from the front, while the 110 hp version had the lower ends of its intake tubes seemingly "hidden" behind the cylinders.

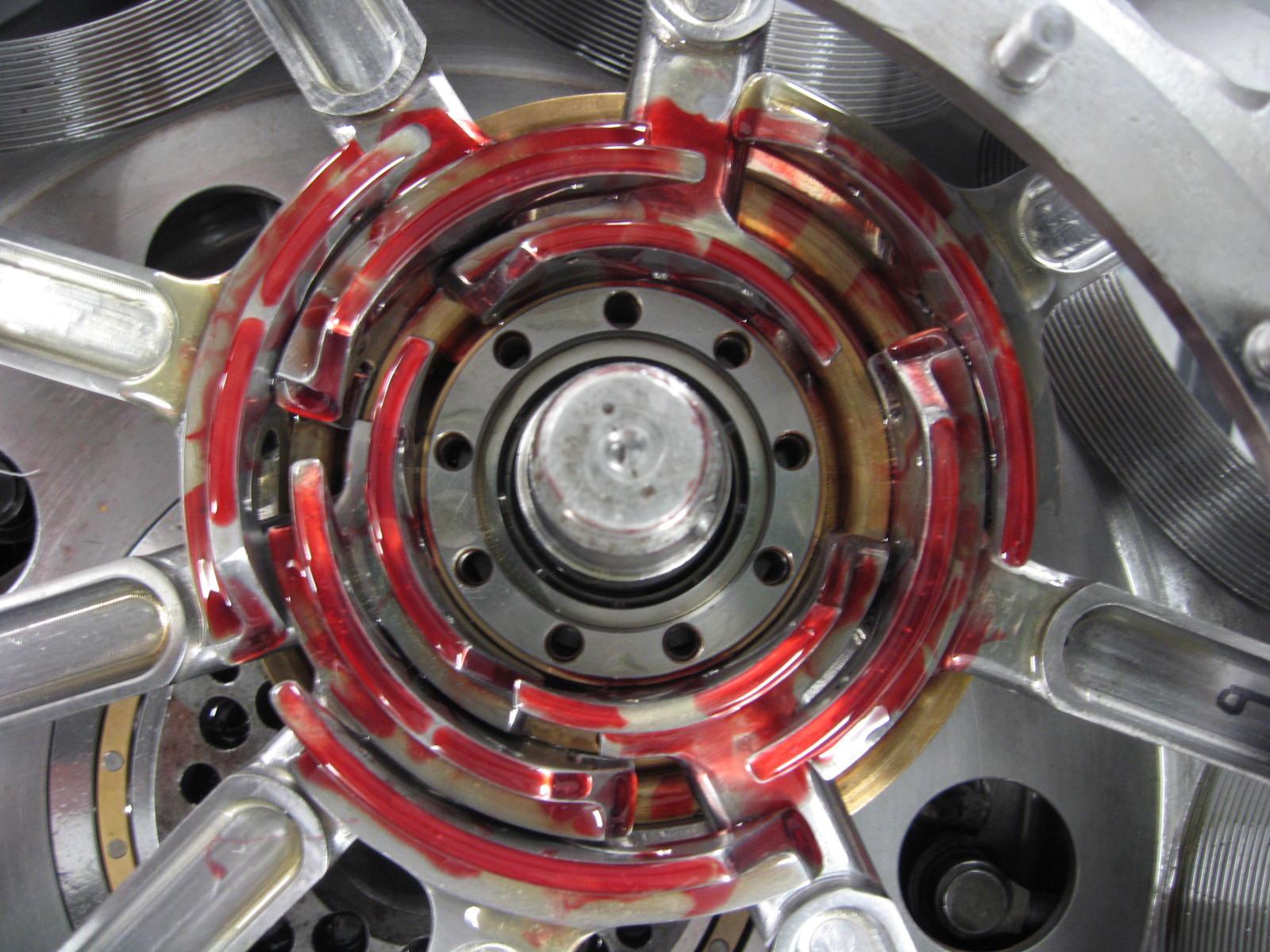

A complicated slipper bearing system was used in the Le Rhône engine. The master rod was of a split-type, which permitted assembly of the connecting rods. It also employed three concentric grooves, designed to accept slipper bearings from the other cylinders. The other connecting rods used inner-end bronze shoes, which were shaped to fit in the grooves. The master rod was numbered as number one and the shoes of numbers two, five and eight rode in the outer groove, the shoes of three, six and nine in the middle groove and four and seven in the inner groove. Although this system was complex, the Le Rhône engines worked very well.

A complicated slipper bearing system was used in the Le Rhône engine. The master rod was of a split-type, which permitted assembly of the connecting rods. It also employed three concentric grooves, designed to accept slipper bearings from the other cylinders. The other connecting rods used inner-end bronze shoes, which were shaped to fit in the grooves. The master rod was numbered as number one and the shoes of numbers two, five and eight rode in the outer groove, the shoes of three, six and nine in the middle groove and four and seven in the inner groove. Although this system was complex, the Le Rhône engines worked very well.The Le Rhône engines used an unconventional valve actuation system, with a single centrally-pivoting rocker arm moving the exhaust valve and the intake valve. When the arm moved down it opened the intake valve and when it moved up it opened the exhaust value. To make this system work a two-way push-pull rod was fitted, instead of the more conventional one-way pushrod. This feature required the cam followers to incorporate a positive action, a function designed in by using a combination of links and levers. This design functioned but it did prevent the incorporation of valve overlap which limits power output. Due to the structural and cooling limitations of the overall engine design the Le Rhône engines produced as much power as they were capable of, regardless.

Applications

Le Rhône 9J |

Le Rhône 9Jb |

|

|

|

|

|

|

|

|

|

Le Rhône 9Jby |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specification

|

|

|

|

|

|

|

|